Yes, I admit it, in my list of favorite dive sites there are two concrete ship wrecks, and my bucket list has another one. I am not talking of ships that were carrying cement when they sank but ships made from concrete. And for the record, I am not crazy!

Technically, they are ferrocement (the terms ferro-cement or ferro-concrete are also used) which is a wire mesh or rebar covered with a mortar of cement. I often get strange looks when I mention concrete ship wrecks but concrete ships were more common than many people realize.

Ferrocement ships is really a proven concept. Joseph-Louis Lambot is credited to be the inventor of the ferrocement process around 1844. Joseph Monier patented a similar process 1867 that applied to buildings which has refined over the years to the concept we now know as reinforced concrete. However, historians believe that the ancient Romans used something similar. In 1848, Lambot built a small boat using iron bars and cement mortar. Later he patented the process in 1855 and one of his boats was displayed at the 1855 World’s Fair in Paris. That boat is now in a museum.

In the early 1900s, barges using the ferrocement process were made in Europe. At the outbreak of WWI, the US Government built a few ships using the process. In 1917, the Portland Cement Association published an interesting pamphlet titled “Concrete Ships A Possible Solution of the Shipping Problem.” It gives a great overview of the history of the ship building process and reasons why the government should build concrete ships. Sadly, the WWI effort was not highly successful.

When WWII was in full swing, the lost of allied shipping was enormous. Rebuilding the ships required massive amounts of steel. The average Liberty Ship used 3,132 tons of steel. Because of the lack of steel, The Wartime Shipping Administration released contracts to build 146 ferrocement ships. By the end of the war, 104 were built in different configurations. Most of these were barges, they were of a similar design of a freighter or tanker, however, had no engine but were pulled by a tug.

The largest barge was the B7-A2 design which was 375 feet long, 360 feet at the water line, with a beam of 56 feet. It had a height of 38 feet of which as much as 26 could be draft. While the cost per shipping ton was just slightly less that the all steel Liberty ships they only used 1,600 tons of steel about half what the Liberty Ships needed. Another benefit was that the steel used in the ferrocement barges was a low carbon grade steel that was not suitable for the other ships.

If you still have trouble accepting a ship made out of concrete, I will direct your attention to the Powell River in British Columbia Canada. The Powell River Breakwater is the largest floating breakwater in the world. To protect a paper mill from the ocean, the mill owners created a wood breakwater which was later replaced with old steel hulled ships. In the late 1940s the steel ships were replaced. There are now ten old concrete ships, one from WWI and nine from WWII forming the floating breakwater. While there has been some patch works and the ships are re-positioned every 5 to 10 years, only the anchor chains have been replaced.

Concrete Ship Wrecks

In my personal top ten dive sites is the YON-146, a B7-A2 design barge, located in Subic Bay Philippines. It is not really a “secret” wreck, just one that not many people dive on. The wreck sits near the mouth of the largest river that empties into the bay, this leads to very unpredictable visibility. Also she rest in 120 feet / 36.5 meters. The ship its upright however much of the interior has become filled with silt from the river. Silt has also filled in around the wreck so the deck is less than 5 meters above the bottom. The sheer size of the vessel means it best for Nitrox and it is barely possible to make one circuit around the vessel on a single tank.

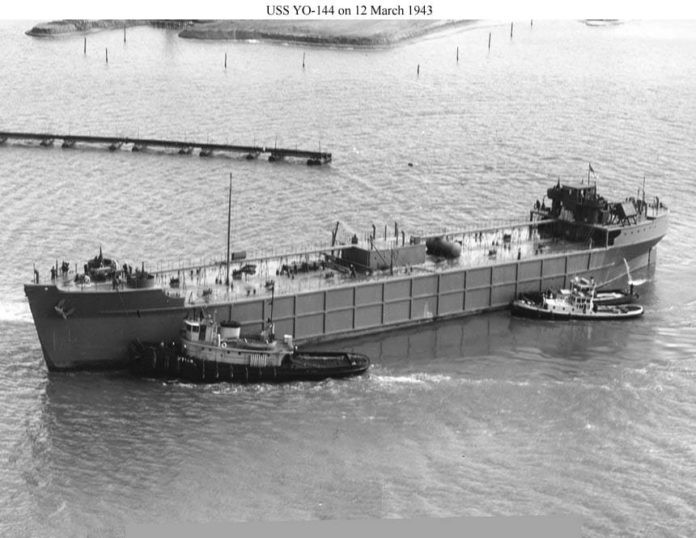

The Concrete ships were built at a rapid pace with generally three being built side by side. YON-146 was built in National City California, starting on 23 Feb 43 and was ready for launch on 16 May 43. She officially entered service on 12 Aug 43.She spent the war doing duty in the pacific. After the war she spent time in Guam and Hawaii. She spent most of 1952 in the Marshall Islands, as a supply vessel for the nuclear testing program Operation Ivy. She returned to Subic Bay and was active until added to the disposal list on 24 Apr 57. YON-146 was lost by accident in July 1957.

There are other concrete ship wrecks in the Pacific area that are now dive sites. In Guam, one was sunk as a breakwater during the war. She is also a B7-A2 design that the local dive operators call the American tanker. In the Koror Harbor of Palau is another ship sunk as a breakwater. Local dive operator call it the cement wreck and it is sometimes identified as the Trefoil-class ( B7-D1 design) concrete barge,USS Lignite (IX-162). I have not fully researched the ship, but have reasons to believe it is not. The USS Lignite sank in an different location in Palau and there is documentation of her as a dive site at that location from 1974.

Many of the concrete ships found new life as breakwaters during the war including two sunk on D-day in Normandy. In December 1948, the coast of Kiptopeke Beach, Virginia became home for nine of the barges to form a breakwater for a ferry terminal. They are still there but the ferry terminal is not.

Divers in the Caribbean have some of these concrete ship wrecks to dive. Off the coast of St. Thomas is the ship WIT Concrete, sitting in 95 feet of water she was one of those built in the National City California shipyard. (on my top list)

S. S. Sapona lies in 17 foot deep water, 4 miles south of Bimini Island in the Bahamas. She is a WWI ship. It a shallow site used for both diving and snorkeling.

More Concrete Ship Wrecks Coming

Going back to Powell River for a moment. It has often been said that Jacques Cousteau stated that Powell River cold water scuba diving is second only to the Red Sea in terms of abundant, colorful marine life. Catalyst Paper Corporation who owns the floating breakwater is trying to make it smaller as the mill does not use as much shore line as before. They recently submitted a plan to sink four of the concrete ships to form an artificial reef. YOGN 82, a sister ship of the one in Subic Bay is the first one planned to become an artificial reef.

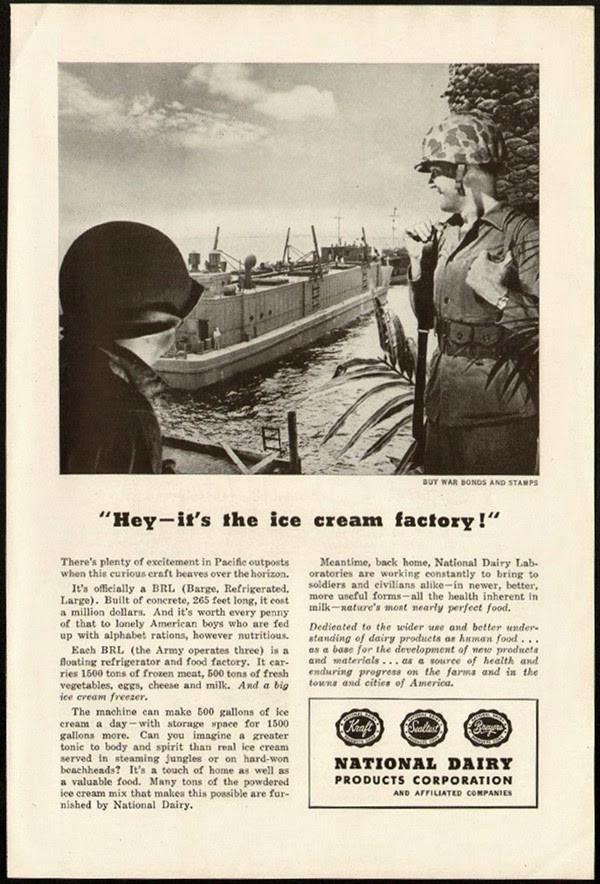

One final remark on the concrete ships, The troops in the Pacific during WWII were sometimes treated to ice cream, compliments of a converted barge.